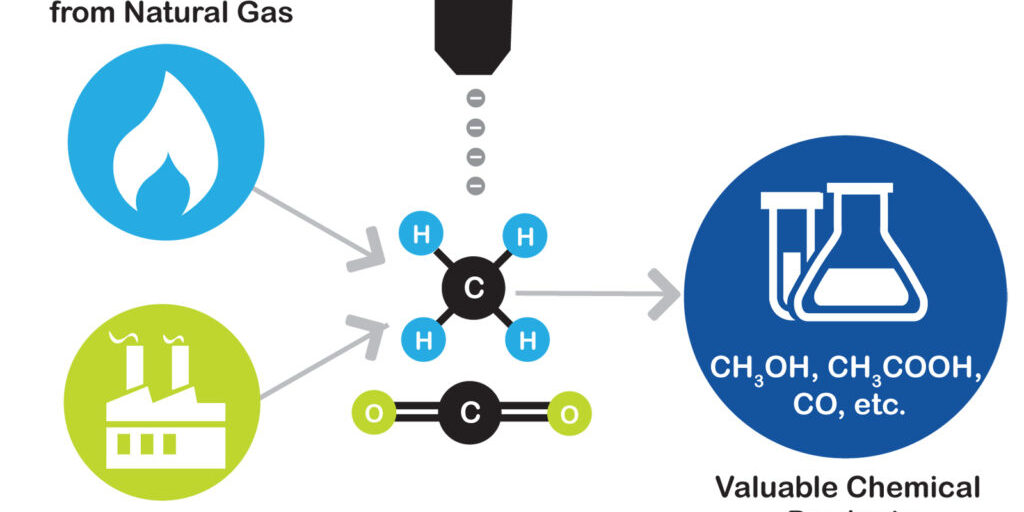

Global demand for power, hydrogen, liquid fuel and chemical production is growing as access to low-cost resources provides new market opportunities. Renewable raw materials can be converted into valuable energy products in minutes instead of millennia.

GTI Energy is working on a portfolio of technologies and processes for transforming natural gas, coal, coke, and biomass into clean power, fuels, and chemicals.

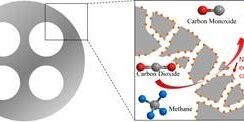

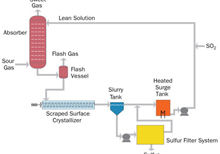

GTI Energy provides technical and economic process expertise and solutions for comprehensive fuels processing. We are developing new technologies to lower the cost of upgrading subquality gas to pipeline and LNG specifications and to provide better approaches to meeting environmental regulations of gas processing facilities.

Our technology platforms for midstream cleanup remove contaminants before the gas is brought to market with advantages in capital cost, operations and maintenance cost, and footprint. GTI Energy researchers have extensive background in gas processing and clean-up technologies to produce gaseous and liquid biofuels suitable for a wide range of applications: pipeline quality gas, liquid transportation fuels, renewable chemicals, and hydrogen.

Key Initiatives

Delivering high-impact, value-added research and commercialization

Producing a Drop-In Gasoline Product or Flexible On-site Power with a Partial Oxidation Gas Turbine (POGT)

Soft Oxidation (SoftOx) Process Mitigates Flaring Issues and Converts Sour Gas to Clean Liquid Fuels

Success Stories

Commercialized Products

Technologies for gasification and gas processing allow alternative and renewable energy resources to supplement traditional natural gas resources. Representative technology developments that have had major market impact include the following:

Learn More

Contact the energy experts today