Cool GTL: A Pathway to Sustainable Fuels

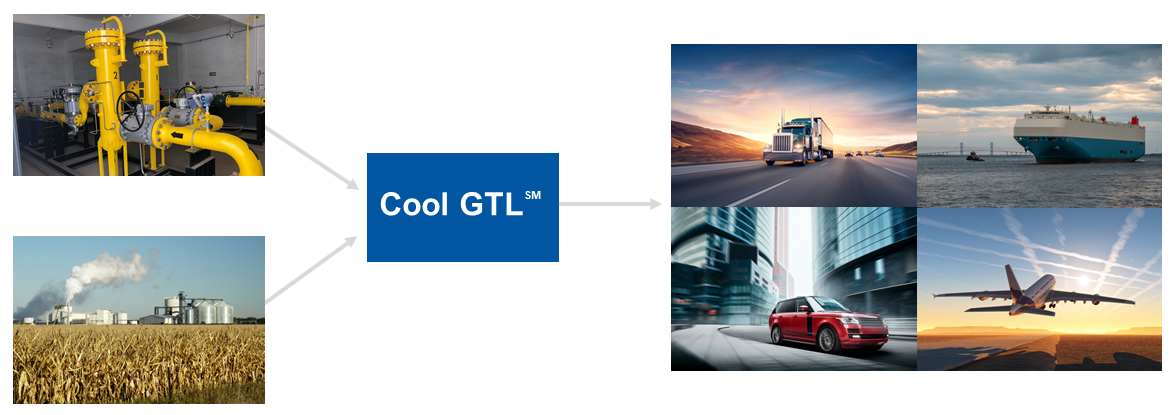

GTI Energy has developed a Cool GTLSM process that uses more carbon than it produces to convert natural gas, RNG and CO2 into high-quality liquid fuels efficiently and affordably, with zero byproduct—driving a modern revolution in the production of transportation fuels.

The simple modular approach reduces cost, shrinks size, and minimizes the carbon footprint of GTL conversion, turning a complicated and expensive process into something commercially viable at small scale. The low-cost system integrates a new, lower temperature, natural gas reforming process (Cool Reforming) and a novel Fischer-Tropsch (F-T) reactor to make high-quality fungible liquids.

GTI Energy is demonstrating large-scale conversion technologies to minimize greenhouse gas emissions from aviation, a traditionally difficult-to-decarbonize sector. Researchers are leading a team on a DOE project to build and operate a fully integrated, fully automated Cool GTL pilot-scale test unit to validate the process at a larger scale. It will run 24/7 with a goal to produce 100 gallons of high-quality jet fuel. Another DOE project will develop and scale up technologies and processes that meet the demands for sustainable aviation fuels while reducing costs.

Benefits

Benefits

- Modular, low-cost GTL

- Small footprint

- Great economics

- Distributed plant locations

Learn More

Contact the energy experts today