GTI Energy can help the industry make informed decisions to manage risk, maximize safety, and achieve optimal system performance. We are combining sound science with predictive models to describe the behavior of systems with complex interactions and estimate the underlying event probabilities. Working with key stakeholders, we are helping to support integration of these results into industry guidelines, standards, and regulations.

Creating an Enterprise Decision Support System (EDSS) Platform to Help Operators Assess and Manage Risk

Creating an Enterprise Decision Support System (EDSS) Platform to Help Operators Assess and Manage Risk

A multi-dimensional risk assessment tool developed by GTI Energy is being leveraged in a project with Intermountain Gas Company and MDU Resources Group. The multi-year effort with Intermountain Gas—a large, diverse organization with 8 utilities in 7 different states—will pull all of the organization’s operations data together under a single enterprise-wide model for risk assessment.

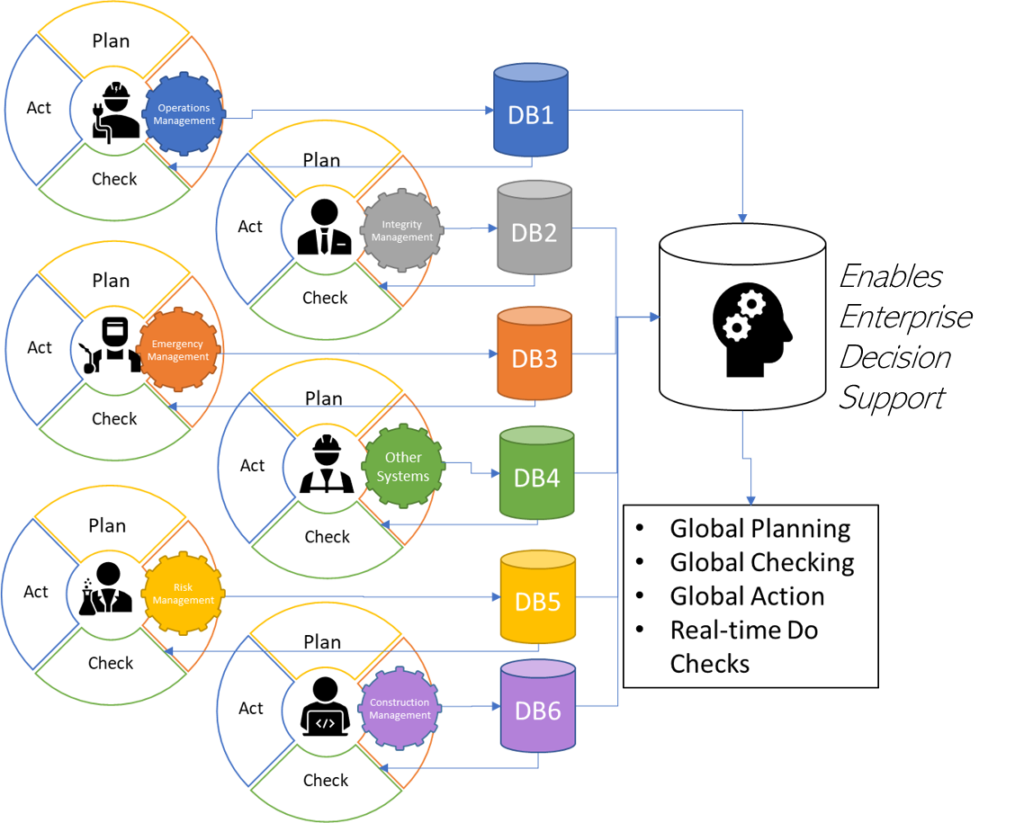

The Enterprise Decision Support System (EDSS) platform integrates gas-system data and knowledge from various sources into a single information platform to support decision making. It utilizes diverse data sets, probabilistic reasoning, and artificial intelligence (AI) to support optimization of capital programs, risk governance, risk management, and analysis through advanced data analytics.

With Operations Technology Development (OTD) funding, a full set of tools for determining fitness-for-service of vintage plastic gas distribution pipe has been integrated into a commercially available AI framework and validated against historic data sets. The tool was previously deployed in a single-source application on WEC/Peoples Gas’ Manlove underground natural gas storage facility.

“I have really enjoyed working with the GTI Energy team and learning from their exciting work. I look forward to continuing our partnership and building an industry-leading risk management model.”

Nicole Garrett, Quality Assurance and SMS Manager, MDU Utilities Group

Developing risk models for natural gas storage operations

Based on recent incidents, PHMSA regulations for minimum standards for natural gas storage operators have been issued to reduce risk for natural gas storage operations.

GTI Energy has an extensive background with risk modeling and risk assessment and has executed research for PHMSA and other natural gas industry organizations related to threat interactions, risk modeling, and the prevention of failures and catastrophic events. A slate of past projects in natural gas storage operations and risk assessment empower our researchers with abundant knowledge.

GTI Energy recently completed a research project for PHMSA to present a thorough and critical review of approaches for preventing catastrophic events, both within and outside the natural gas industry. The results from this project enable operators to select and enhance the most appropriate approaches and models and ultimately issue guidelines for effective implementation in risk models and integrity management programs.

GTI Energy has the expertise to develop a risk model to assess the current state of storage field and storage operations. The model will include parameters such as data collected throughout the life of the field (maintenance records), well logs, engineering design documents and data, completion records, and similar information.

Once the threats are identified, a scoring key to develop likelihood of events occurring, as well as the consequences of the events, will be developed. This risk analysis will provide a baseline understanding of the risks of the storage field. This baseline understanding will provide a numerical, relative scoring for risk, and will also provide the basis for further development of an absolute or probabilistic risk assessment as the available information and risk approach is supplemented with system and failure frequency data.

GTI Energy can also develop a prevention and mitigation (P&M) plan for an organization. Standard operating procedures would be reviewed and modified to ensure that they align with regulations and industry best practices. An integrity verification and monitoring plan would be developed based on the risks identified, along with an emergency response plan to help guide company crews in the event of an incident.

Assessing MIC/gas quality risk in underground natural gas storage

Natural gas derived from unconventional sources such as shale and renewable natural gas can contain microorganisms associated with souring and corrosion. In addition, other constituents and naturally occurring water in storage caverns can also be sources of contamination. Owners/operators of underground natural gas storage facilities need to ensure that the integrity of their assets are in proper working order.

Data collected in this new project will augment information regarding the source of contamination in soured gas wells. It will also provide an initial assessment of whether there is an increased risk to accepting renewable natural gas into natural gas storage fields from a microbiologically influenced corrosion (MIC) perspective.

A preliminary guidance document for assessing MIC risk is being developed to maintain optimal production of gas storage wells. Conclusions made using the guidance document will create an early-warning gas-management marker for MIC to inform prevention/mitigation strategies to address gas quality and corrosion issues.

Developing tools to evaluate risk in vintage polyethylene pipes

A two-year project with U.S. Department of Transportation Pipeline and Hazardous Materials Safety Administration (DOT PHMSA) and partners was recently completed. It delivered an integrated set of quantitative tools that provide a structured approach to evaluating the latent risk in vintage polyethylene pipes, such as Aldyl-A, that are common in gas distribution systems.

Outcomes from the project include a prototype endoscopic structured-light inspection tool for assessing stress risers that can access pipe through keyholes, comprehensive risk models, and methods to optimize maintenance and replacement programs based on collected data.

Leveraging GTI Energy’s legacy of expertise in plastic pipe and piping products, this project on vintage pipe used dynamic testing methods for polymeric materials. This effort delivered useful lifetime prediction models for Aldyl A piping systems and provided meaningful engineering guidance to integrity management teams.

Learn More

Contact the energy experts today