Gases and liquid fuels are an important part of today’s global energy mix, and they are positioned to play a leading role in addressing hard-to-decarbonize sectors.

Within this broad portfolio of energy solutions, renewable LPG (r-LPG)—essentially renewable propane and butane produced using renewable resources—offers an option with significantly lower carbon footprint than traditional LPG.

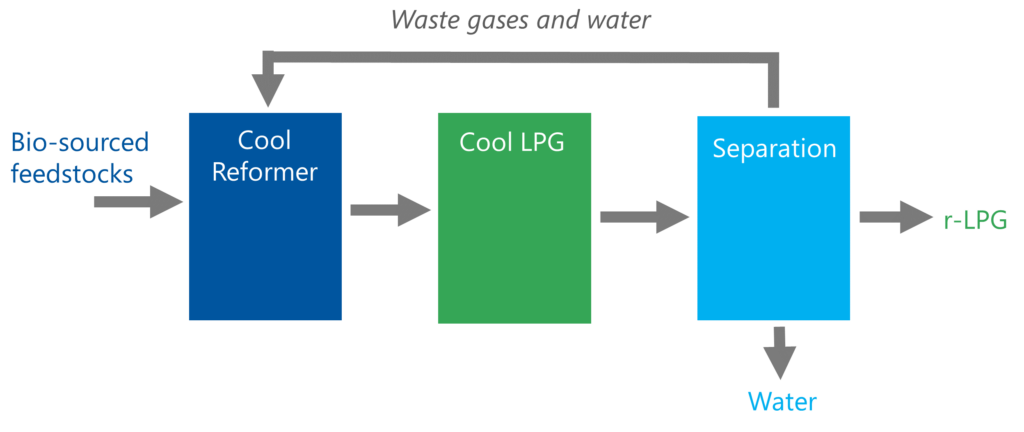

GTI Energy is responding to this need by working with multiple global partners to investigate and develop technologies for the “on-purpose” production of r-LPG. Our Cool LPG technology converts biogas, bio-syngas, or biogenic carbon dioxide and green hydrogen into r-LPG, a clean-burning drop-in fuel chemically identical to fossil-based LPG. These feedstocks can be sourced from landfills, woody biomass, agricultural facilities, and wastewater treatment plants—even potentially municipal solid waste—and converted into r-LPG for cooking, heating, and transportation.

Cool LPG is set to be one of the lowest-cost, highest-yield technologies to produce clean r-LPG. This fuel supports cleaner air and enhances standards of living in historically disadvantaged and underserved communities in the U.S. and in developing nations around the world.

Cool LPG is set to be one of the lowest-cost, highest-yield technologies to produce clean r-LPG. This fuel supports cleaner air and enhances standards of living in historically disadvantaged and underserved communities in the U.S. and in developing nations around the world.

Today, the Cool LPG research team, based at GTI Energy’s laboratory facilities in metropolitan Chicago, continues to further refine the Cool LPG technology and accelerate its deployment for heating, cooking, and transportation.

The Net-Zero 2050: U.S. Economy-Wide Deep Decarbonization Scenario Analysis, developed by the Low Carbon Resources Initiative led by GTI Energy and the Electric Power Research Institute, finds that a broad portfolio of low-carbon energy technologies is needed for affordable, reliable, and rapid transitions of energy systems.

GTI Energy Tech Talk: Delivering a renewable fuel for people across the globe

Collaborating for Widescale Deployment

GTI Energy has licensed our Cool LPG technology to BioLPG, LLC—sister company to UN-backed NGO affiliate Global LPG Partnership (GLPGP)—to provide early-stage collaboration and build facilities in developed economies. A global consortium including Green LG Energy S.r.l of Italy, Friedrich Scharr KG of Germany, and rLPG North America is providing financial support. The consortium is focused on accelerating Cool LPG to market and providing the potential of r-LPG to commercial, industrial, and household LPG users to help meet decarbonization goals. Each of the members invested in the partnership represents dozens of energy entities across several countries, with a common goal to support access to clean energy and enhance quality of life.

Making a Global Impact

GTI Energy’s mission is driven by dual imperatives—the need to deeply decarbonize energy systems and supply the energy needed to support economic growth around the world. Access to low-cost and low-carbon fuels should be available to all communities everywhere. Renewable LPG can offer a clean alternative to disadvantaged, rural, and indigenous communities in the U.S. and in developing nations where r-LPG can be used as a healthy, reliable substitute for solid fuels, such as wood and charcoal.

GTI Energy entered into an exclusive global licensing agreement with the Global LPG Partnership (GLPGP)—a non-profit Public-Private Partnership backed by the United Nations—to aggregate and deploy Cool LPG to African countries to help them rapidly and sustainably transition to r-LPG for cooking. GLPGP’s vision is to help transition one billion people to the use of r-LPG for cooking by 2030.

News

The latest on Renewable LPG

Renewable LPG demonstrates GTI Energy’s long-term commitment to advancing actionable research and real-world technologies that support both global decarbonization and expanded access to low-cost, clean energy to improve quality of life around the world.

- GTI Energy’s Cool LPG Technical Paper Awarded Best Presentation Honor at LPG Week Global Science Conference

GTI Energy News Release (11/21/2023) - Global Energy Consortia Unite to Accelerate Market Speed of Cool LPG Technology

BioLPG LLC News Release (02/10/23) - Going Global: Expanding the Reach and Impact of GTI’s Cool LPG Technology as a Clean Fuel Alternative

GTI Energy News Release (07/28/21)

GTI Energy’s technical expertise and collaborative approach to partnerships drive important research outcomes that advance transitions to low-carbon, low-cost energy systems around the world.