A Clear Focus on the Future

Hydrogen Generation

GTI Energy focuses R&D efforts on the generation of clean hydrogen from different feedstocks through a variety of processes. Although hydrogen burns with zero emissions, it is often produced in a way that creates GHG emissions, but there is a lot of potential to reduce the GHG impact based on the way it is created. Hydrogen can be produced with low or no carbon emissions, but selecting the best hydrogen generation technology often depends on the application.

By incorporating carbon capture and/or carbon sequestration in a cost-effective manner, clean hydrogen can be generated from hydrocarbons for large scale or smaller distributed production. The process of creating hydrogen via electrolysis is being pursued to store renewable electricity from wind or solar in a form that will provide dispatchable lower-carbon energy to consumers that could be used for remote and back-up power generation.

GTI Energy has developed technologies to make hydrogen on-site from renewable feedstocks to minimize costs of hydrogen transportation. GTI Energy’s micro-scale steam methane reforming (SMR) technology utilizes renewable gas from digester plants or landfills to generate hydrogen on-site. GTI Energy has a long history of building and operating on-site hydrogen generation and dispensing stations to fuel vehicle fleets. Another example is gasifying renewable agricultural or woody biomass to generate renewable hydrogen—one of the major components of the syngas created by gasification. GTI Energy has decades of expertise in biomass conversion, gas quality, clean-up, and processing which is being used to support projects from SunGas Renewables, Inc.

Advancing transparency and credibility to hydrogen markets

The Open Hydrogen Initiative is laying the foundation for clean hydrogen marketplaces through an open-source, standardized accounting methodology for hydrogen production at the facility level.

Capabilities

Low-carbon and renewable hydrogen production

- Hydrogen production technology development, design, and testing

- Compact hydrogen generator

- Liquid phase reforming

- Biomass gasification

- Ammonia-based production

- System modeling

- Field demonstration support

Key Initiatives

Sub-surface Technologies for the Generation and Production of Low-carbon Hydrogen from Hydrocarbon Resources

Demonstrating GTI Energy’s Innovative Low-carbon Hydrogen Production Technology for Decarbonization in UK HyPER Project

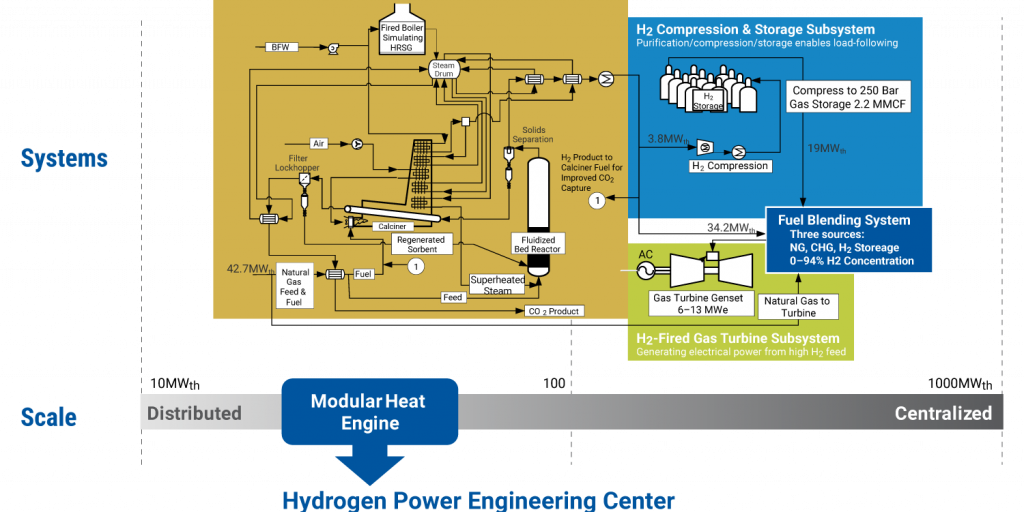

Laying the Groundwork for a Hydrogen Power Engineering Center to Advance Production of Low-cost Decarbonized Hydrogen Power Generation

Success Story

Converting Biogas to Hydrogen to Run Military Fuel Cell Vehicles

GTI Energy and the Department of Defense successfully completed a project to condition wastewater treatment biogas into a high-quality biomethane fuel that is converted to hydrogen (via steam reforming) to operate military base vehicles with hydrogen-powered fuel cells. Hydrogen generated at Joint Base Lewis-McChord’s water treatment plant was used to power 19 fuel cell forklifts and a fuel cell shuttle bus for a 12 month demonstration. GTI Energy designed, built and installed the waste gas clean-up system and hydrogen generation infrastructure at the base.

GTI Energy and the Department of Defense successfully completed a project to condition wastewater treatment biogas into a high-quality biomethane fuel that is converted to hydrogen (via steam reforming) to operate military base vehicles with hydrogen-powered fuel cells. Hydrogen generated at Joint Base Lewis-McChord’s water treatment plant was used to power 19 fuel cell forklifts and a fuel cell shuttle bus for a 12 month demonstration. GTI Energy designed, built and installed the waste gas clean-up system and hydrogen generation infrastructure at the base.

Learn More

Contact the energy experts today